Figure 1. Resolution vs Part size for different metal AM processes. Based on the figure by DigitalAlloys

Direct Energy Deposition (DED)

A comparison of multiple metal 3d printing methods

Direct Energy Deposition (DED) is a family of Additive Manufacturing technologies that uses a directed heat source to melt a feedstock material. DED of metals allows additive manufacturing of large scale metallic components at a much higher deposition rate compared to other AM technologies, such as Powder Bed Fusion (PBF). In general components manufactured with a DED process are characterized by a large part size and relatively low resolution/part complexity when comparing them with PBF. A schematic classification of the AM process according to resolution and part size is proposed in Figure 1.

The Additive Manufacturing technology that is used at RAMLAB, WAAM, is a member of the DED family.

Common DED processes

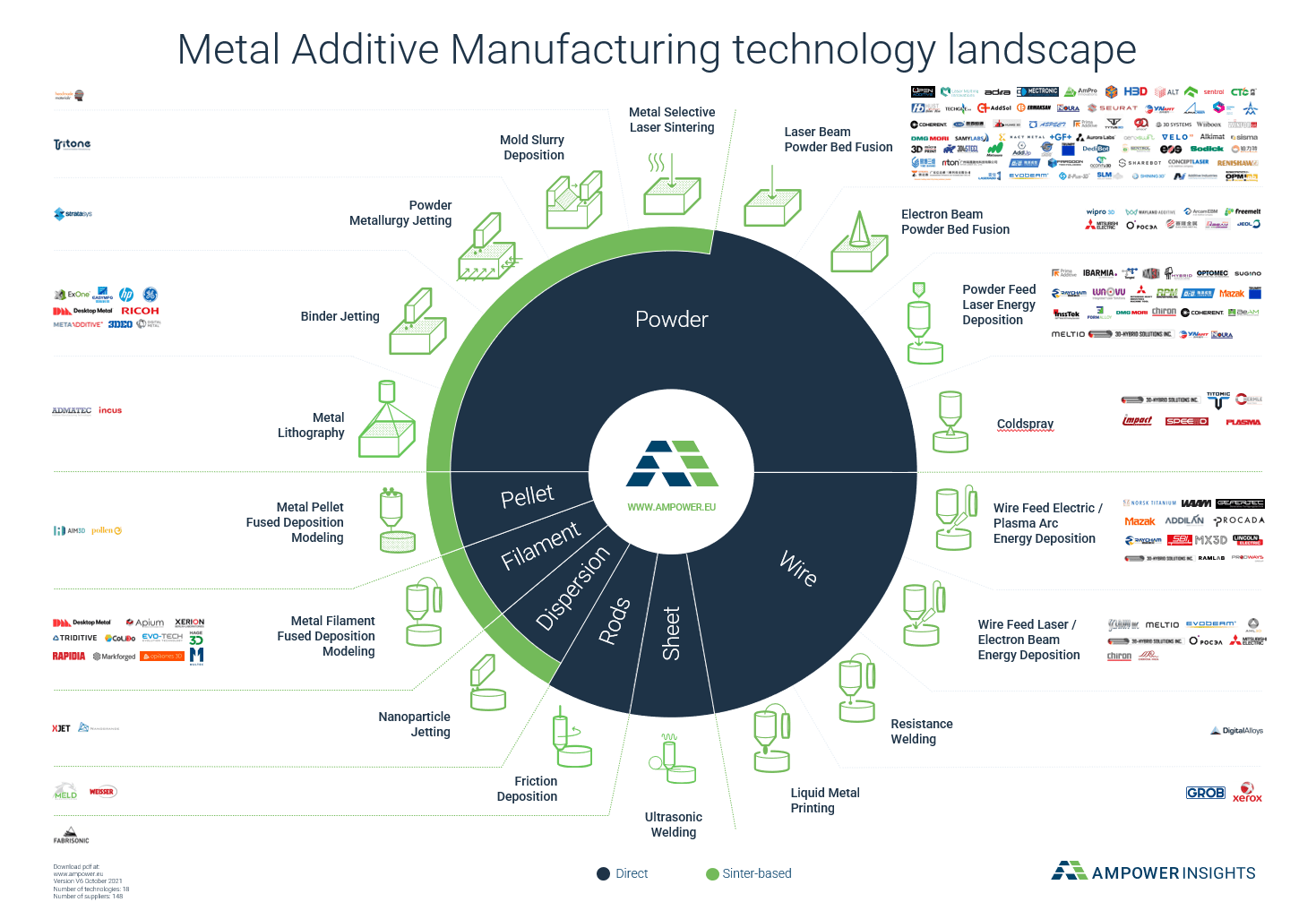

Over 18 different metal 3D printing processes are known. Ampower Insights made an overview and classification of the most important procedures with the known suppliers, which you can find in figure 2. The latest version of the model can be downloaded on the AMPower website.

With DED technologies, the feedstock material (in the form of wire or powder) is fed through a narrow nozzle and molten by a heat source. Depending on the process, the heat source can be an electric arc, a laser or electron beam, or a plasma. The most common DED processes are Wire Arc Additive Manufacturing (WAAM), Laser Metal Deposition (LMD), Wire Laser Additive Manufacturing (WLAM) and Electron Beam Additive Manufacturing (EBAM). In Figure 2 the different configurations are shown.

The most common DED processes are shown in Figure 3. DED technologies differ in the type of heat source and material feedstock. Examples of heat sources used in DED technologies are electric arc, plasma arc, electron beam and laser beam. The material feedstock can be in the shape of wire or powder. The DED technology RAMLAB uses is WAAM (Wire Arc Additive Manufacturing).

Figure 2: An overview of the most important procedures with the known suppliers, courtesy of AMPower

EBAM

Electron Beam Additive Manufacturing. Learn More

WLAM

Wire Laser Additive Manufacturing. Learn More

Figure 3. Most common DED processes on the market

Advantages of WAAM

The main advantages of a WAAM process over the other AM technologies are:

- high production rate up to 5 kg/h;

- Large build volume (>1x1x1 m) ;

- mechanical properties outperform casted and compete with forged material;

- low cost of the wire feedstock;

By adopting a WAAM system, RAMLAB has access to a wider material availability, higher production rates, higher flexibility and lower machine costs compared to other DED technologies (as visible in Figure 4)

Figure 4. Comparison of strengths and weaknesses of different metal AM processes. Based on assesment by Stewart Williams.

Post-processing of DED

The outcome of the WAAM process are components in a near-net-shape design, that must be machined to their net-shape. When comparing it with traditional manufacturing processes (Figure 5), WAAM has lower resolution and higher surface roughness (~1 mm) therefore requiring a machining process. By manufacturing components in a near-net-shape a relatively fast delivery can be guaranteed.

Figure 5. Comparison of WAAM (Wire DED) with other traditional processes. Courtesy of DigitalAlloys